Cooling Towers in Indonesia, Asia

We have been specializing in the production of cooling towers for more than 40 years, although when you go online you will find several companies that specialize in the production of cooling towers. , you can also find various portals that display a list of the top 10 cooling tower manufacturers, but it is easy to get confused when buying a cooling tower.

We are one of the top cooling tower manufacturers in Indonesia in terms of design, manufacturing, installation and maintenance of closed cooling towers. We have agents in Indonesia and we have undertaken many projects locally, including in the petrochemical industry. Food industry, pharmaceutical industry, etc.

Our advantage:

* Innovative design using the latest cooling tower technology.

* Industry leader, we have built over 20,000 cooling towers.

*Conservative thermal ratings.

* Long life structure.

* Compact yet powerful weatherproofing.

* Proven and reliable.

* Simplified maintenance.

Noise reduction treatment of cooling towers

Noise reduction treatment of cooling towers

The noise sources of cooling towers mainly come from four aspects: fan intake and exhaust noise, water spray noise, fan reducer and motor noise, and cooling tower water pump, piping and valve noise. Among them, falling water noise is a unique noise source of cooling towers. It is a steady-state water noise generated by the large-scale continuous liquid impact of cooling falling water on the pool water in the tower.

The sound source sound level of this noise is about 80dB (A), and the spectrum is mainly composed of high-frequency (1000-16000 Hz) and medium-frequency (500-1000Hz) components, with a peak at around 4000Hz. Due to the long wavelength of sound, strong penetration ability, and insignificant sound attenuation, it is difficult to control.

On the other hand, the turbulence and friction-induced pressure disturbances generated by the air in the top guide pipe of the cooling tower, as well as the vibrations generated by the blades and the air, will radiate noise outward. These aerodynamic noises are one of the main sound sources of cooling towers.

In addition, falling water noise is also a noise source that cannot be ignored. When the circulating water of the cooling tower falls freely through the packing layer to the water trough, impact noise will be generated, and its intensity is proportional to the square of the water speed. The measurement results show that the A-level noise of the falling water reaches 70dB, which is a...

FBH-400 cross flow cooling tower installed in Russia

FBH-400 cross flow cooling tower installed in Russia

ZHX Cooling Towers in Vietnam’s Pharmaceutical Industry

ZHX Cooling Towers in Vietnam’s Pharmaceutical Industry.Efficient ZHX cooling towers are widely used in the pharmaceutical industries.

Cooling Tower Replacement Project in Saudi Arabia

A brand-new unit is on its way to our valued manufacturing customer in Saudi Arabia. This customer wanted to replace an old competitor’s unit.

BHX Cooling Tower will be sent to Tanzania Injection Molding Factory.

BHX Cooling Tower will be sent to Tanzania Injection Molding Factory.Timely delivery and high-quality service have always been our goal.

ZNX Evaporative Condenser will be sent to Türkiye.

5 sets of ZNX Counterflow Evaporative Condenser will be sent to Türkiye.Our products have been widely used in the petrochemical industry.

ZHX Cooling Tower made its way up to Ecuador

This Series ZHX-1840 Cooling Tower made its way up to Ecuador this month. Our customers come from the petrochemical industry and they have great trust in our products and services.

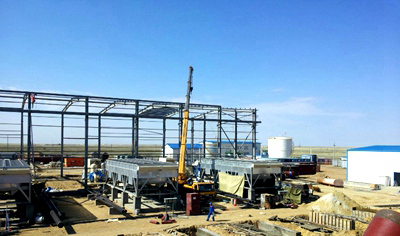

Installation of FRP Cooling Tower in Steel Works

Our FRP cooling tower has a water treatment capacity of 3000m3/h and is currently being installed in a large steel plant. Our products have undergone their inspection.Our products are widely used in industries such as coking, steelmaking, metallurgy, etc

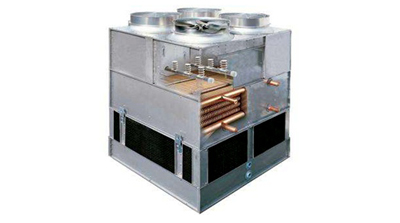

Градирня закрытого типа

Градирня закрытого типа, в отличие от открытой градирни, имеет замкнутое пространство теплообменных труб (радиаторы из гальванизированной или нержавеющей трубы), где и циркулирует охлаждаемая жидкость.

В закрытых мокрых градирнях охлаждаемая вода остается всегда чистой – рабочая жидкость не вступает в контакт с воздухом, а герметичные радиаторы защищают от загрязнений. Подаваемая из чаши насосом вода омывает радиатор конденсатора с воздушным охлаждением и передает тепло потоку воздуха, циркулирующему внутри градирни с помощью радиальных вентиляторов .

1. Мощные вентиляторы позволяют устанавливать в градирне несколько рядов теплообменника, за счет чего теплопередающая поверхность увеличивается, а температура максимально снижается.

2. Специальный конструктив градирен с высокой охлаждающей способностью (противоточная компоновка наиболее эффективна для теплообмена). На всасывании воздуха обеспечивается равномерность распределения воздушных потоков, за счет чего достигается высокий КПД градирни.

3. Эффективная водораспределительная система:

— уникальная форма форсунок, которые устанавливаются в определенном порядке друг напротив друга (факел распыла), обеспечивает равномерный расход воды и эффективное ее распыление по всей теплообменной поверхности.

Price Increase Effective January 1, 2021

In the last few months, key commodities such as carbon steel, galvanized steel, stainless steel, and aluminum have increased significantly. While we have delayed the onset of this higher-priced material, we must implement a price increase moving forward. We will continue to monitor commodity price increases and advise if further HACST price increases are required.

We remain committed to offering the highest quality products and services to our customers. If you have questions or concerns about how this price increase may affect your project, please contact our team of Marketing Engineers for additional assistance.

CCOIC

China Chamber of International Commerce

China Chamber of International Commerce, or CCOIC, was established in 1988 with the approval of the State Council of the People’s Republic of China. Affiliated to China Council for the Promotion of International Trade (CCPIT), CCOIC is a nationwide chamber of commerce comprised of enterprises, groups and other business organizations that are engaged in international commercial activities in China.

CCOIC adopts a membership system and its main responsibilities include: promoting economic and trade exchanges and cooperation between China and foreign countries; reflecting interest appeal of enterprises to international organizations and government departments of China and foreign countries on behalf of Chinese business community; participating in constitution and promotion of international trade rules; facilitating enterprises to participate in international competition and cooperation; safeguarding legitimate rights of its members, and actively advocating social responsibility and public welfare among business circles.

By mid-December 2019, CCOIC has 246,000 member enterprises, including most central SOEs, national financial institutions, a large number of well-known private enterprises and foreign-funded enterprises. CCOIC has become one of the most influential business associations in China.

With the aim of building a hub-like chamber of commerce, CCOIC has institutional cooperation with other business associations from home and abro...

HACST Expands Line of Cooling Tower

Because of the continuous growth of global orders, we have built another plant with an area of 5000 square meters and two production lines with an annual capacity of 800 units, mainly producing closed circuit cooling tower and evaporative condenser.

HACST, Inc. is Open for Business: A Letter from Our President/CEO

Dear HACST Customers,

As you know, China is the place where the epidemic was first discovered, and it is also the best country in the world to control the epidemic. We have a population of 1.4 billion, and only tens of thousands of people have been infected. This is a great achievement. We have gone through the most difficult time, and now we have a normal work life, so our business will not be affected by the virus.

Under the severe situation of global epidemic outbreak, our sales will achieve a small growth in 2020, which benefits from the strong strength of our motherland and the people-oriented policy. We will continue to provide quality and timely service to customers all over the world.

On behalf of the entire HACST family, I wish to say that our hearts go out to all those impacted by this terrible pandemic. This too shall pass, but during this difficult time please know that HACST is made up of men and women you can count on for a lifetime.

Ms. Li

President & Chief Executive Officer

HACST, INC.

When is it necessary to replace the PVC fill?

After 5-8 years of normal use of general cooling tower, it is necessary to replace the pvc fill. In case of no normal maintenance, the fill needs to be replaced once every two years. If the following abnormalities occur to the fill in the tower, it shall be replaced in time to make the thermal efficiency of the whole tower reach the predetermined goal.

1. Scaling. The packing in the tower has scale, which is generally calcium carbonate scale attached to the fill, which is stone like and hard in texture.

2. Sinking. The fill of the tower body is stained with heavy mud ash, and sometimes a large number of algae grow, which makes the fill sink and cannot be used.

3. Aging. After long-term use, due to the erosion of water and air, the fill is gradually old, brittle and easy to be damaged. The aging of high temperature tower packing is faster than that of ordinary tower, and it is generally replaced once every 4 to 6 years.

4. The fill of cooling tower is seriously damaged due to improper selection or operation. Each type of cooling tower has design work index value, and improper selection will directly lead to serious damage and scrap of cooling tower. However, in the important working indexes such as inlet water temperature and configuration tonnage, if the working index is greater than the design index value due to improper operation, it will also cause serious damage to the filler.

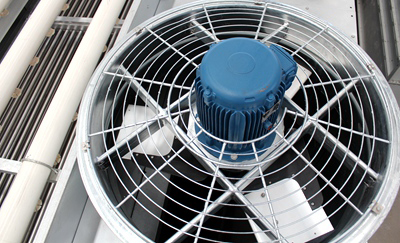

Fan maintenance of closed cooling tower

Fan maintenance of closed cooling tower? Fan is the main component of closed cooling tower. The quality of fan and the air volume of fan affect the working efficiency of cooling tower. The fans used in the closed cooling tower are made of FRP, aluminum alloy and other materials. Different materials also have great differences in quality and service year. Therefore, proper maintenance is more important. Pay attention to a few points in the maintenance of fans of closed cooling tower.

Fan maintenance of closed cooling tower?

1.Add lubricating oil regularly. The blade rotation of the fan is driven by the high-speed fan. The shaft of the motor is prone to lack of oil, resulting in poor rotation and increased friction. Reduce the service life of the fan, improve the damage rate, add lubricating oil regularly and keep the speed smooth.

2. Calibrate the air duct regularly. When some wind turbines, especially those made of glass, are rotating at high speed, there will be the problem of improper inclination of the wind turbines, and the friction of the wind blades will be damaged. It is necessary to regularly send professional maintenance personnel to correct the position of the wind turbines, or to reinstall the position. Ensure the average and reasonable clearance between the air duct and the air blade.

3. Replace the damaged blades in time. Generally, there are three blades. If one of the blades is damaged, the wind force will be different early, and the wind force will be unbal...

Daily maintenance of closed cooling tower

Daily maintenance of closed cooling tower.Closed cooling tower is not suitable for direct contact with the outside air, which may cause corrosion and oxidation, greatly reducing the service life of cooling.

Daily maintenance of closed cooling tower? For the cooling fluid of closed cooling tower, if it contacts with the outside world for a long time, it is easy to be polluted and produce toxic and harmful substances. The closed cooling tower must be cleaned in time.

In addition, we should pay attention to the problem of clogging the spray buckle, because if we do not clean it for a long time, especially if the water quality of the cooling tower is not clean, it will form scale, biological algae sludge and other dirt, it will block the heat exchanger and its filter and a series of problems, which will directly cause the low heat exchange efficiency.

For the closed cooling tower, it can not be in the state of high-temperature heat load for a long time. In this case, it actually causes the fatigue and corrosion damage of its metal, which will directly lead to the perforation and leakage of the closed cooling tower equipment.

When to add refrigerant to closed cooling tower

When is the refrigerant added to the closed cooling tower? When the ambient temperature is about 0 ° C, it can be considered to add coolant on the pipeline or the circulating water tank, so as to increase the surface temperature of the closed cooling tower, so as to facilitate anti freezing.

When is the refrigerant added to the closed cooling tower?

Add antifreeze: when the local low ambient dry bulb temperature (air temperature) is – 10 ° C or lower than – 10 ° C, 20-30% high content antifreeze should be added, with the actual ice free freezing as the criterion, and the user can grasp it flexibly according to the actual situation.

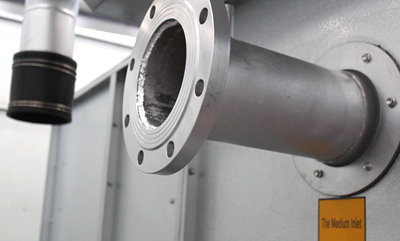

The working fluid (water, oil or other liquid) of the closed cooling tower flows in the coil, the outer wall of the coil is wrapped by spray water, the heat of the fluid is transferred through the pipe wall, and the water and air are saturated with hot and humid steam. The heat is discharged into the atmosphere by the fan. The spray water is cooled by PVC radiator during the circulation, and flows in the same direction with the fresh air into the air. The coil mainly depends on the wet The important feature of the operation principle is that it is possible to inhibit the formation of scale on the outer wall of the coil.

The closed cooling tower adopts totally closed circulation, without impurities entering and with small pollution; the application of the closed cooling tower can effectively improve the utilization coefficient of the ...

Why the cooling tower can only drop to the temperature near the wet bulb?

Why the cooling tower can only drop to the temperature near the wet bulb? When the cooling tower is used, it can cool down quickly, but the temperature is about the wet bulb temperature, but it can’t be lowered to 3 ℃ lower than the wet bulb temperature.

The temperature drop of the cooling tower can be said to be close to the local wet bulb temperature! But not more.

Cooling tower is a large-scale refrigeration and cooling equipment which takes away heat through water evaporation and heat absorption. Want to know why, need to know what is wet bulb temperature first, want to measure wet bulb temperature, need to put wet bulb thermometer in ventilated place, read wet bulb temperature in air flow remember scale, it is wet bulb temperature.

Because the water we spray on the surface of the condenser absorbs heat. As the temperature rises, it condenses into water vapor and evaporates continuously. The water vapor will mix with the air, and the water vapor with high temperature will exchange heat with the air continuously. To achieve a balance, on the contrary, if the temperature of the condenser is lower than that of the wet bulb, the temperature in the air will be absorbed.

When cooling, because of the influence of various factors, it is only near the wet bulb temperature. There is an error. We control the error within 3 degrees of the wet bulb temperature!

What are the characteristics of fill used in closed cooling towers?

There is a large height difference between the air inlet and the air outlet, so it is not easy for the air to flow in and out, and the temperature of the intake air can be lower. The heat exchange power of the countercurrent tower is high. The air inlet louvers of the closed cooling tower can be arranged along the circumference or around it, so the air inlet is more uniform and the cooling effect is good. On the external dimensions, the diameter of the circular tower is larger than that of the square tower with the same function, and the side length is also larger. For these reasons, the application of the circular tower that is constrained by the area is affected.

When the direct cooling beam of the closed cooling tower fill block has a small support, the supporting beam should have a small width, and the structure and ventilation resistance should be small. The beam spacing should be equipped with a simple support lining plan. When the grid is supported, the span of the grid simply supported and the span of the support beam should be together, and the grid corrosion function should be compatible with the fill. The fill function and thermal function should be combined with the general comments of the fan function, and the cooling capacity should be selected under the same planning conditions. For film packaging, when the combination of the same type of paper and the height are different, it should be calculated. When the planned temperature difference is large, a larger p...